Types of Hydraulic Pumps and Selection Criteria

Types of Hydraulic Pumps and Selection Criteria

-

29 October 2025

- Posted by: HM LIFT

Hydraulic Systems and Pump Varieties

Hydraulic systems convert hydraulic power into mechanical energy by using the principle of fluid incompressibility. Serving as the heart of these systems, hydraulic pumps transmit energy and ensure smooth operation. Therefore, selecting the right pump is crucial for achieving maximum efficiency and performance.

Types of Hydraulic Pumps

- a) Piston Pumps

Piston pumps are preferred for applications requiring high pressure and efficiency. In these pumps, pistons move back and forth within cylindrical chambers to pressurise the fluid, resulting in superior performance.

Features:

- High pressure capacity

- Excellent efficiency

- Durable and long-lasting construction

- Provides consistent flow

Applications:

- Construction machinery

- Industrial presses

- Mining equipment

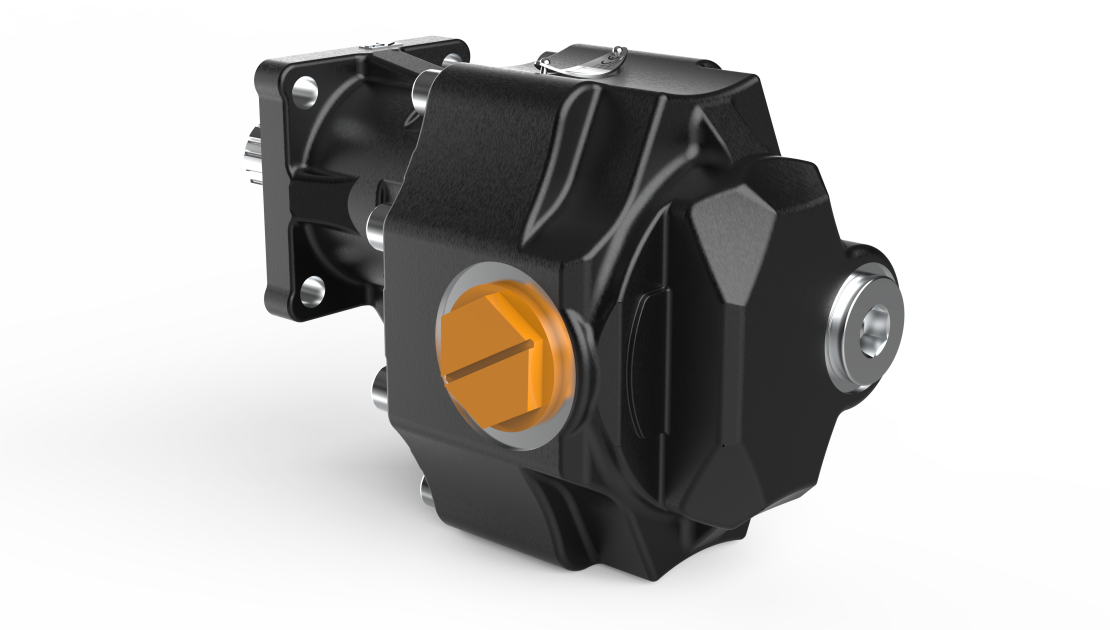

- b) Gear Pumps

Gear pumps are known for their simple and robust design. Fluid movement occurs as the driving gear rotates the idler gear, creating a reliable flow within the system. Due to their cost-effectiveness, gear pumps are frequently chosen by small and medium-sized enterprises.

Features:

- Simple and compact design

- Reliable and durable

- Low cost

- Provides constant flow

Applications:

- Lubrication systems

- Agricultural machinery

- Hydraulic power units

- Tipper trucks

- Agricultural trailers

- Cranes

Hydraulic Pump Selection Criteria

When selecting a hydraulic pump, several factors must be considered:

- Pressure and Flow Requirements: Piston pumps are suitable for high-pressure applications, whereas gear pumps are ideal for low-pressure systems. Accurate system analysis is essential.

- Fluid Type and Properties: For example, peristaltic pumps are ideal for viscous fluids, while gear pumps are suitable for lubrication systems.

- Operating Environment: Piston pumps provide better durability under harsh conditions, while gear pumps offer the advantage of lower maintenance needs.

- Energy Efficiency: Vane pumps are energy-efficient and help reduce operational costs.

- Ease of Maintenance: The simplicity of gear pumps makes them easier and more economical to maintain.

HMLİFT Hydraulic Pumps

HMLİFT offers a wide range of hydraulic pumps designed to deliver exceptional quality and durability. Its gear pumps are renowned for their compact design and dependable performance, while piston pumps provide powerful solutions for high-pressure and high-efficiency applications.

Advantages of Gear Pumps:

- Simple and compact structure

- Reliability and long service life

- Cost-effective

- Steady and consistent flow

Advantages of Piston Pumps:

- High pressure capacity

- Energy efficiency

- Durability and extended lifespan

Conclusion

The type of hydraulic pump used in a system should always be chosen based on the specific requirements of the application. With the right selection, both performance and cost efficiency can be optimised. HMLİFT continues to provide high-quality gear and piston pumps, offering reliable hydraulic solutions across various industrial sectors.