What Is a Gear Pump?

What Is a Gear Pump?

-

29 October 2025

- Posted by: HM LIFT

Understanding Gear Pumps

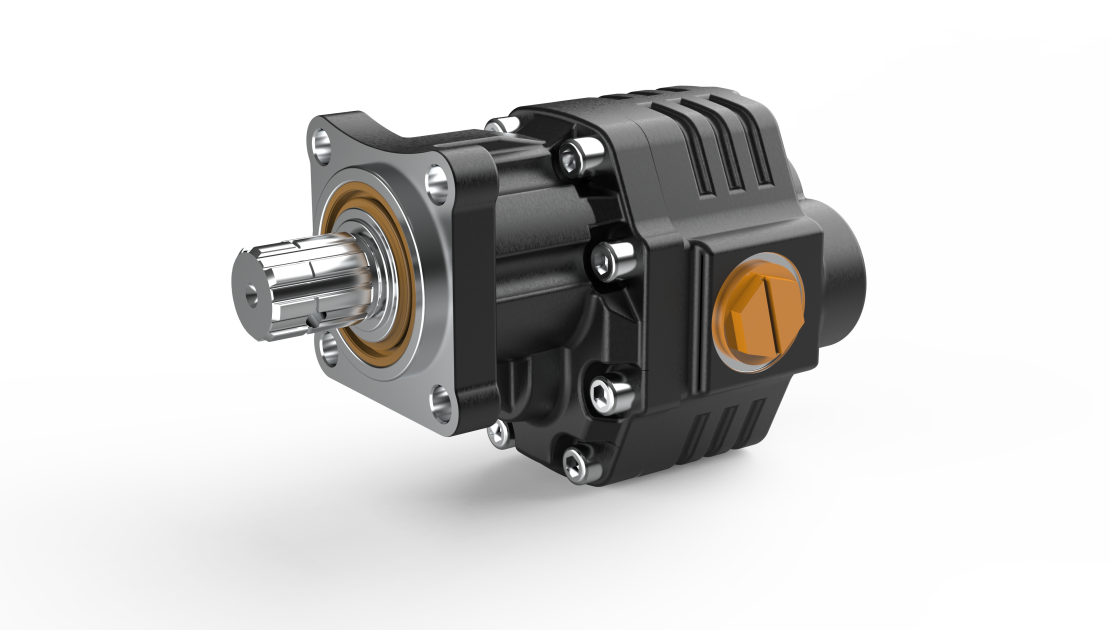

Among the various pump types, the gear pump is a widely preferred choice for industrial applications.

The gear pump was invented by Johannes Kepler in the early 17th century. This hydraulic pump is primarily used in power transmission systems. It operates by receiving mechanical drive from the power take-off (PTO) of a truck, lorry, or electric motor, converting mechanical energy into hydraulic energy. Additionally, it generates high pressure against the resistance within the system.

Gear pumps are one of the most commonly used types of positive displacement pumps. Inside a gear pump, there are two gears — a driving gear and an idler gear — mounted parallel to each other. The external teeth of these gears direct the flow of hydraulic oil, while the sliding bearings attached to the pump body and cover maintain their alignment on the central axis.

Furthermore, the body and cover surrounding the gears guide the hydraulic oil flow through suction and discharge ports, ensuring smooth and efficient operation throughout the system.

Operating Principle

The pump is driven by the power transmitted from a truck, lorry, or electric motor. As the two gears engage and rotate, they initiate the movement of the hydraulic oil. As the gears rotate and separate, a partial vacuum is created, allowing the oil to flow from the suction port into the pump chamber.

The narrow clearances and high rotational speed minimise oil backflow. As the gears continue to rotate, they trap the fluid and carry it around the casing from the suction side to the discharge side. Thanks to their robust construction, these pumps operate safely even under extremely high pressures and can handle high-viscosity fluids with ease.

Applications

This pump type offers reliable hydraulic solutions across a variety of industries. It is widely used in agricultural machinery, industrial production lines, and mobile hydraulic systems. In addition, it provides efficient performance in heavy-duty machinery and vehicles for applications such as lubrication, lifting, and pressure generation.

Owing to their compact design, gear pumps are ideal for installations in confined spaces. Their durable construction ensures long service life and reduced maintenance requirements. Consequently, gear pumps are a cost-effective and dependable solution for diverse industrial applications.

Conclusion

With their simple design and high performance, gear pumps have become indispensable components in modern hydraulic systems. They combine efficiency, reliability, and strength — making them a trusted choice for industrial power transmission applications.