Differences Between Piston Pumps and Gear Pumps

Differences Between Piston Pumps and Gear Pumps

-

29 October 2025

- Posted by: HM LIFT

Hydraulic Pumps: Piston and Gear Pump Solutions

In hydraulic systems, pumps play a decisive role in determining overall performance and efficiency. Among them, piston pumps and gear pumps are two of the most commonly used types, each offering distinct advantages depending on the application.

Piston Pumps

Piston pumps are prominent in applications requiring high pressure and flow rates. The reciprocating motion of pistons pressurises and moves the fluid within the system.

Advantages:

- High Pressure Capacity: Piston pumps deliver powerful solutions for heavy industry and construction applications.

- High Efficiency: They utilise energy effectively, minimising power losses.

- Durability: Their robust structure ensures long-term, reliable operation even in demanding conditions.

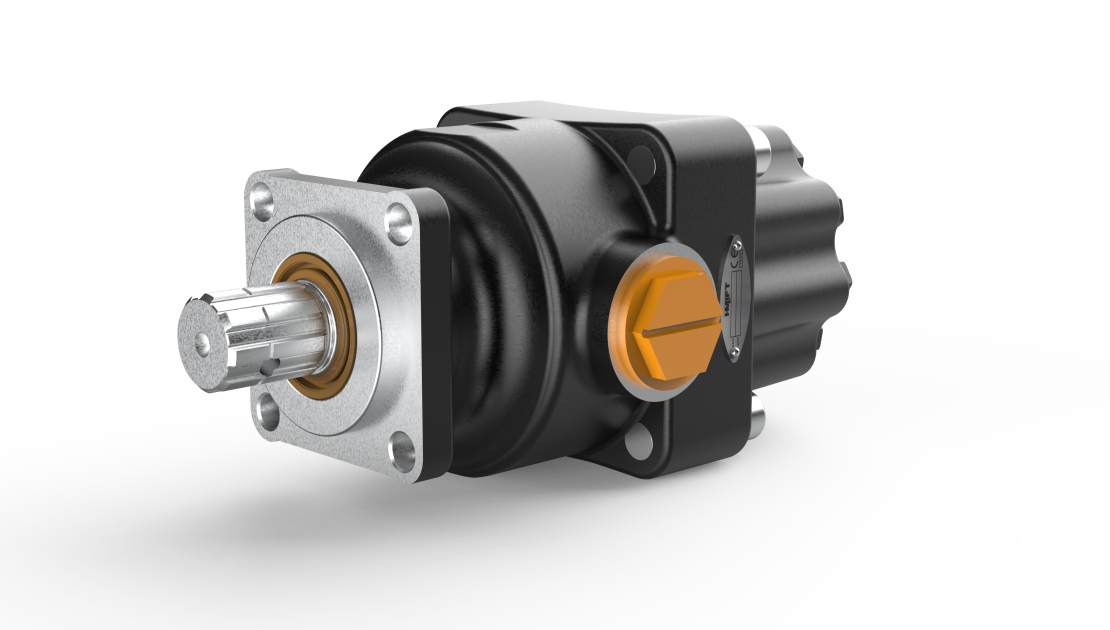

Gear Pumps

Gear pumps are recognised for their simple and reliable design. The rotation of two interlocking gears enables fluid movement through the system.

Advantages:

- Simple Design: Compact construction allows for easy maintenance.

- Low Cost: More economical compared to piston pumps.

- Durability: Made from wear-resistant materials, ensuring a long service life.

- Continuous Flow: Provides steady performance in constant-flow applications.

HMLİFT Piston and Gear Pumps

HMLİFT offers an extensive range of hydraulic pumps that combine high quality, durability, and performance.

Piston Pumps:

HMLİFT piston pumps provide reliable, high-pressure performance for heavy industry, construction, and mining applications. Their user-friendly design simplifies maintenance and reduces operational costs.

Gear Pumps:

HMLİFT gear pumps feature a compact design suitable for a wide range of industrial applications. Their cost-effectiveness and reliability make them an economical choice, while still maintaining the company’s high-quality standards.

Single and Bi-Directional Gear Pumps

Single-Directional Gear Pumps

In single-direction models, the fluid moves in only one direction — drawn in through the inlet port and expelled through the outlet port.

- Simple Design: Ideal for small to medium-scale applications.

- Durability: Strong housing and materials ensure long service life.

Bi-Directional Gear Pumps

Bi-directional pumps allow flow in both directions, with reversible inlet and outlet ports.

- Versatility: Easily adaptable to a variety of applications.

- Flow Adjustment: Enables simple direction change and flow control.

- High Efficiency: Saves energy and enhances overall system performance.

HMLİFT Solutions

HMLİFT provides both single and bi-directional gear pumps designed to meet the specific demands of the hydraulic industry. While single-direction pumps offer a compact and cost-effective solution, bi-directional pumps provide flexibility and multi-functionality for more advanced systems.

Conclusion

In summary, piston pumps are ideal for applications demanding high pressure and superior efficiency, whereas gear pumps offer simple, economical, and reliable solutions. HMLİFT stands out in the industry by maintaining uncompromising quality and reliability across both pump types, providing customers with dependable hydraulic performance.